Predictive Maintenance

powered by VAHLE

Since the invention of the copper conductor rail, VAHLE stood for technical progress. With the Smart Collector, we developed the world’s first intelligent current collector. Its sensors monitor the movement data of the current collector and, due to the IDA-Anaylse method, detect anomalies soon enough to avoid unplanned downtimes.

Our promise

With the learning system, which was specially developed for EMS and AS/RS systems, we strengthen our promise of quality.

The Smart Collector acts as an efficiency boost for your intralogistics processes.

Increasing productivity

Sustainable cost reduction

Reduction of reaction times

Minimization of downtimes

Increase in service quality

Reduction of storage costs

Planning reliability

The system in detail

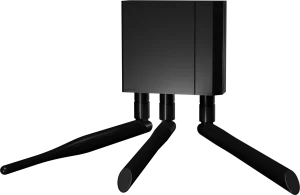

Current collector with sensors

3D sensors adapted to the current collector arms record the movements (stroke and deflection data) of the current collector during operation. The function of the current collector is not affected in any way. The data is transmitted to the main unit for analysis.

Main Unit

Measurement data is processed and evaluated using the Intelligent Dynamic Anomaly Analysis (IDAA) method. This is done in real time directly on the main unit. The system has variable interfaces and is compatible with various positioning and data transmission systems.

Data transmission

If the main unit detects reproducible anomalies, a message is transmitted to our certified data center via the data transmission (e.g. LTE or SMGM). A permanent transmission or storage does not take place.

Software

The analyzed measurement data are visualized by means of VAHLE software solutions and enable plant operators to perform ongoing condition monitoring as well as various service options, which can be called up digitally using any terminal device.

Our software

Visualization of data and reporting of anomalies in the traffic light system

Unlimited data volume as well as data storage in the certified data center

Dashboard access from all devices

„Know today what will happen tomorrow. With the Smart Collector, VAHLE is giving the starting signal for the digitalization of the conductor system.“

Jessica Genz | Product Management, VAHLE Group

Early Bird

Take the chance and secure your Early Bird Smart Collector Bundle, consisting of hardware and software package at a special price. After the inspection run, you will receive a report on the condition of your plant and can avoid unplanned plant shutdowns today. You also benefit from our workshops and further information on future developments.

Plug & Play

No structural modifications necessary

Simple replacement of the existing current collector

Installation of the main unit and data transmission

Data transmission without affecting the IT infrastructure

Analysis software can be used on any terminal device

Analysis & evaluation

Analysis of stroke and deflections of the current collector

Measurement of carbon wear

Precise positioning detection of anomalies

Push notifications in case of anomalies from the TARGET values

Analysis reports for planning optimal maintenance

Advantages of the Smart collector

- 1 Easy implementation with Plug & Play

- 2 High compatibility with various systems

- 3 Simple installation in existing plants possible

- 4 Data analysis for predictive maintenance

- 5 Reduction of maintenance costs

- 6 Increasing process reliability

- 7 100% self-sufficient system solution

Market insights

70%

of manufacturing companies are not fully aware of the condition of their plant.

Vanson Bourne global study

15%

of time is spent on maintenance with predictive maintenance. With "reactive" maintenance, it is almost three times as much time.

Roland Berger

220000€

is the average cost of a one-hour machine downtime for manufacturing companies.

Aberdeen report

30%

of maintenance costs can be saved through predictive maintenance. Unplanned downtime could be reduced by 70%.

Accenture

82%

of companies have had at least one and an average of two outages in the last three years.

Vanson Bourne global study